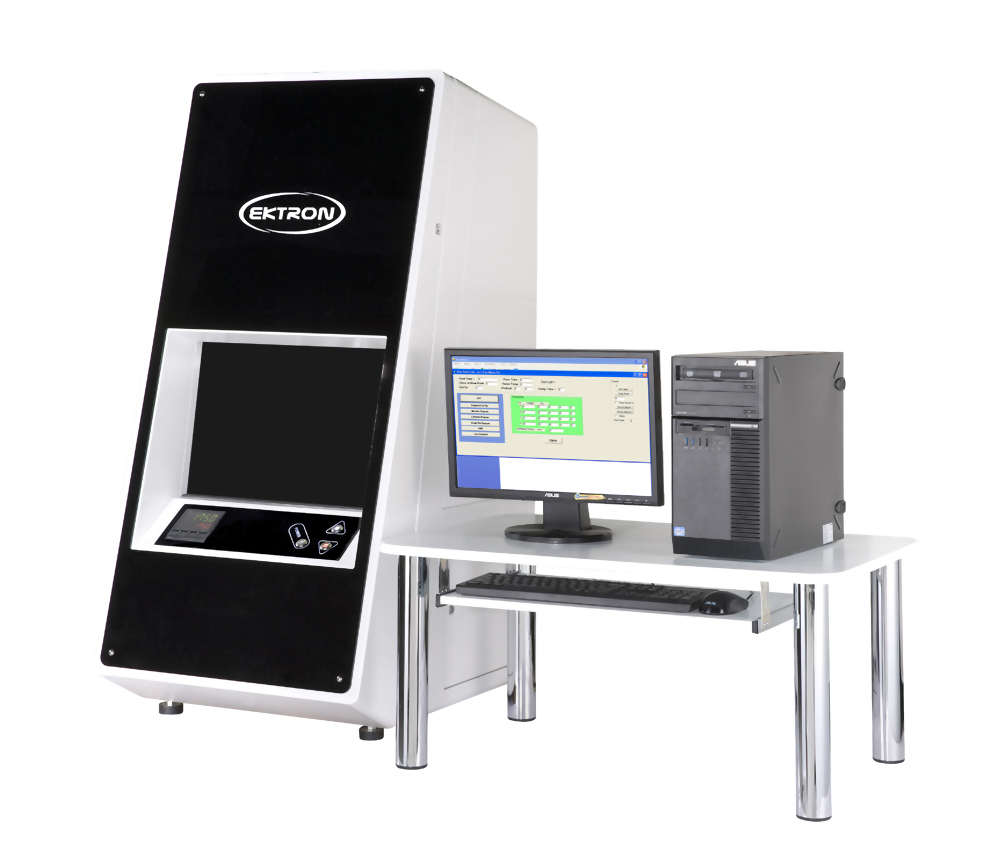

Blow Point Tester

The system helps user to improve product’s polymer characteristics to improve the productivity, energy saving, resistance and durability.

• Mold shape: Wedge-type

• Heating Method: Special Designed Temperature Heating Structure to get uniform temperature distribution

• Test temperature: R.T. +10℃~180℃

• Testing Points: Four

• Temperature Sensor: Pt100 Platinum Resistance Sensor

• Temperature Accuracy: +/-0.3゜C

• Power: 1Phases, 220+/-10V, 50/60Hz

COMPONENTS

Basic components

• One set of test machinery

• Including: wedge mold, temperature sensor 4 units, a set of mold heating system, controlling system..etc.

Sub-Machinery

• Including: Computer with windows system,19”LCD color monitor, Hp color-jet printer, Mouse, Keyboard.

BLOW POINT MEASURING

• Analyze the air hole inside the rubber sample

• To determine the most suitable curing time

WEDGE-TYPED MOLD

The curing process behavior can be analyzed in different thickness.

TEST DATA

• Heat Diffusion Constant

• Equivalent Curing Time

• Blow Point

SPECIAL FUNCTIONS

• Great Sensitivity of temperature control and uniformity

• Sensitivity precise thermal temperature sensor

• Determine the thermal diffusion constant by measuring the temperature at real-time during curing process in wedge-typed mold.

• Cutting device to easily cut the wedge type sample

• Optional equip with CCD image processing function to understand the bubble limiting point